Most silicon solar cells are completely rigid, but researchers in China, Germany and Saudi Arabia have now succeeded in making them bend and flex like paper. The new flexible cells have a baseline power conversion efficiency of 24%, and they retain 96.03% of this efficiency after 20 minutes of flapping in a laboratory-generated version of wind. They are also robust to temperature changes, losing just 0.38% of their efficiency after cycling between temperatures of –70 and 85 °C for two hours.

Conventional silicon-based solar cells make up 95% of all solar cells on the market today. After decades of development, these cells are very efficient at generating electricity from sunlight. Their main drawback is that silicon is a brittle material that cracks easily when bent, meaning that standard silicon solar cells cannot be deployed on undulating or flexible surfaces.

Thin-film solar cells made from other materials, such as amorphous silicon, Cu(In,Ga)Se2, CdTe, organics or perovskites, are attractive alternatives in many ways. However, they often contain elements that are toxic (such as lead or cadmium) or scarce and expensive (such as indium or tellurium). They also suffer from low power conversion efficiency and are chemically unstable under normal operating conditions.

Shearing rather than fracturing

Scientists have long known that textured crystalline silicon wafers begin to crack at certain sharp interfaces that form between pyramid-shaped features on their edges.

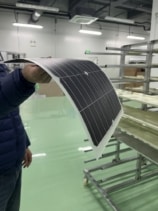

In the latest work, a team of researchers led by Wenzhu Liu of the Shanghai Institute of Microsystem and Information Technology, Chinese Academy of Sciences, used this fact to improve the wafers’ flexibility. They did this by blunting the crack-initiating interfaces with chemical and plasma etching. Once blunted, the wafer no longer fractures. Instead, it forms a microscopic network of cracks that enables it to be bent and even rolled up.

After treating the wafers in this way, the researchers demonstrated that they could use them to make heterojunction solar cells. When assembled into large flexible modules with an area greater than 10,000 cm2, the new cells had a power conversion efficiency as high as 23.4%. An anti-reflective coating based on magnesium fluoride increased the efficiency further, to 24.6%.

Ultrathin flexible solar cells get an efficiency boost

Resistant to vibrations and repeated bending

“These devices are resistant to vibrations and repeated bending (1000 side-to-side bending cycles) and could be made into lightweight large-area flexible solar modules,†Liu tells Physics World. “They may be good for building-integrated and car-integrated photovoltaics where such properties are needed.â€

While the new cells can withstand conditions that mimic winds with speeds of 30 m/s for 20 minutes, they are not yet robust to high-speed hailstones. The researchers, who report their work in Nature, say they are now looking into ways of solving this problem.