An elastocaloric cooling system that absorbs heat as tension is released in bundles of metal tubes has been developed by a team of researchers in the US and China. Led by Ichiro Takeuchi at the University of Maryland, the team’s scheme achieved a cooling performance on par with other caloric materials, and could pave the way for commercial use in the not-too-distant future.

Conventional refrigeration systems usually employ gases that have powerful greenhouse effects if released into the atmosphere. As a result, researchers are developing alternative solid-state refrigeration technologies based on caloric materials. These materials undergo temperature changes when exposed to external magnetic or electric fields, or in response to mechanical stress or pressure. As well as avoiding harmful chemicals, cooling systems based on caloric materials could also be more energy efficient than existing refrigerators.

So far, this research has focused mainly on magnetocaloric materials – but more recently, elastocaloric materials have emerged as even more promising candidates for commercial caloric cooling. Among these materials is the highly elastic and easily manufactured alloy nickel titanium (NiTi).

Under tension

As Takeuchi’s team first showed over a decade ago, thin wires of this alloy can expel large amounts of heat when under tension, and absorb it when the tension is released. “About 12 years ago, we discovered that NiTi can experimentally display a large span in temperature, which you can feel by hand,†Takeuchi recalls. “At the time, we demonstrated this by adding tension to readily available NiTi wires. This is how we started making elastocaloric devices.â€

The researchers then set to work on developing commercially useful cooling applications. However, implementing elastocaloric cooling on a large scale has turned out to be a significant technical challenge. The main problem is that repeated cycles of tension and release damage NiTi wires, limiting their practical lifetimes.

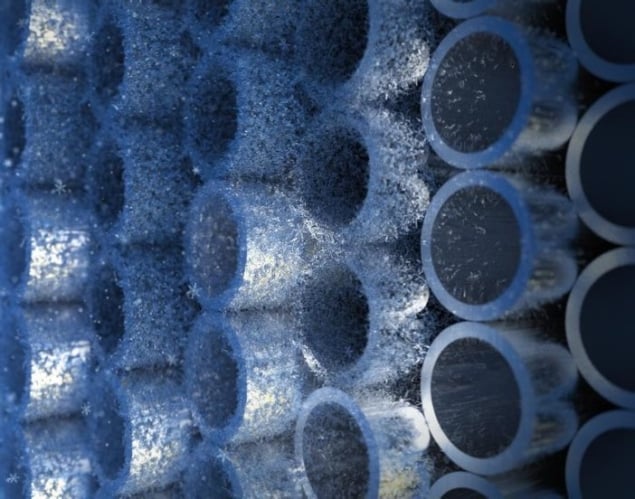

To address this challenge, Takeuchi’s team developed a novel heat exchange system whereby water is pumped through bundles of NiTi tubes. “It took us a long time to overcome various engineering challenges, but with our recent demonstration, we were able to demonstrate what we envisioned 10 years ago. We are using water as heat exchange fluid – making the water colder, so it can be used in turn for refrigeration or air conditioning,†Takeuchi explains.

The team used two quantities to gauge the success of the approach. The first is “delivered cooling powerâ€, which describes the rate of heat removal. The second is “temperature spanâ€, which describes the difference in temperature between the water at each end of the system. “For these two important figures, we have been able to achieve 260 W and 22.5 K, respectively,†says Takeuchi. The researchers maximized each of these values in turn, simply by adjusting the operation sequences of valves in their heat-exchange system.

Catching up

These latest results are an example of how elastocaloric materials are catching up with the cooling performance of their magnetocaloric counterparts, and could soon be feasible candidates for commercial cooling systems.

Solid-state cooling is achieved via electric field induced strain

However, Takeuchi concedes that the practical use of elastocaloric materials may still be some way off, as it will likely require more advanced materials to be developed first. “The high stress required for NiTi is still a problem, but there are materials on the horizon, other superelastic materials, which are known to exhibit elastocaloric effects with much smaller stress,†he says.

“These materials are less developed, and not commercially available yet, but we believe further development of these materials and implementing them in low-stress cooling systems is a really exciting prospect.†Takeuchi’s team has already drawn out plans for a compact, elastocaloric wine cooler, and hopes to demonstrate a successful prototype once these materials are available.

The research is described in Science.